text.skipToContent

text.skipToNavigation

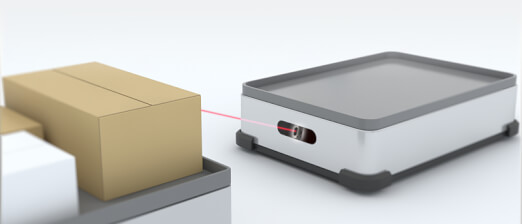

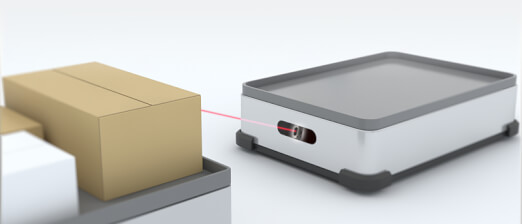

The new E3AS sensors provide the longest sensing distance of 1,500 mm in their class, with the smallest body and the industry's first antifouling coating for revolutionary ease-of-use.

The E3AS Series adopts the TOF (time of flight) method, which effectively resolves these issues for increased versatility. E3AS Sensors can be used, for example, in high-mix conveyor lines carrying products of various colors and shapes, and assembly lines with restricted space for sensor installation. The industry’s first antifouling coating on the sensing surface reduces false detection and maintenance frequency in environments where oil or dust scatters, or steam generates.

2. Detecting varying colors and materials enables fast evaluation and adjustment. With conventional photoelectric sensors, prior evaluation or positioning was required for each sensing object. The E3AS Series detects sensing objects varying in colors and materials by the set distance, reducing evaluation and adjustment time.

3. Industry-first antifouling coating prevents contamination on the sensing surface (Patent Pending). The antifouling coating on the sensing surface of the E3AS Series prevents water droplets, oil, and dust from sticking to the sensing surface, and keeps the lens from fogging as well. This reduces false detection and cleaning frequency.

4. Laser welding technologies for different materials/metals ensure sealing to avoid sensor failures (Patented). The E3AS Sensor case is made of stainless steel (SUS316L). Our patented laser welding technologies enhance the sealing and adhesion between the parts of the case, reducing failures in enviroments with water (IP69K) and oil (IP67G).

2. Detecting varying colors and materials enables fast evaluation and adjustment. With conventional photoelectric sensors, prior evaluation or positioning was required for each sensing object. The E3AS Series detects sensing objects varying in colors and materials by the set distance, reducing evaluation and adjustment time.

3. Industry-first antifouling coating prevents contamination on the sensing surface (Patent Pending). The antifouling coating on the sensing surface of the E3AS Series prevents water droplets, oil, and dust from sticking to the sensing surface, and keeps the lens from fogging as well. This reduces false detection and cleaning frequency.

4. Laser welding technologies for different materials/metals ensure sealing to avoid sensor failures (Patented). The E3AS Sensor case is made of stainless steel (SUS316L). Our patented laser welding technologies enhance the sealing and adhesion between the parts of the case, reducing failures in enviroments with water (IP69K) and oil (IP67G).

E3AS Series offers entirely new ways to use reflective photoelectric sensors

The new E3AS sensors provide the longest sensing distance of 1,500 mm in their class, with the smallest body and the industry's first antifouling coating for revolutionary ease-of-use.

- Wider sensing range of 50 to 1,500 mm frees users from selecting sensors depending on sensing distance.

- Stable detection for various workpieces reduces evaluation and adjustment time.

- Compact body eliminates restrictions on installing locations.

The E3AS Series adopts the TOF (time of flight) method, which effectively resolves these issues for increased versatility. E3AS Sensors can be used, for example, in high-mix conveyor lines carrying products of various colors and shapes, and assembly lines with restricted space for sensor installation. The industry’s first antifouling coating on the sensing surface reduces false detection and maintenance frequency in environments where oil or dust scatters, or steam generates.

Features and benefits:

1. Smallest body and longest sensing distance of 1,500 mm in its class. The E3AS Series, with a wide sensing range of 50 to 1,500 mm, eliminates the need to select different sensors based on application. Users can select either a model with a metal or plastic case to meet their installation environment requirements. Their small size enables installation in confined spaces.2. Detecting varying colors and materials enables fast evaluation and adjustment. With conventional photoelectric sensors, prior evaluation or positioning was required for each sensing object. The E3AS Series detects sensing objects varying in colors and materials by the set distance, reducing evaluation and adjustment time.

3. Industry-first antifouling coating prevents contamination on the sensing surface (Patent Pending). The antifouling coating on the sensing surface of the E3AS Series prevents water droplets, oil, and dust from sticking to the sensing surface, and keeps the lens from fogging as well. This reduces false detection and cleaning frequency.

4. Laser welding technologies for different materials/metals ensure sealing to avoid sensor failures (Patented). The E3AS Sensor case is made of stainless steel (SUS316L). Our patented laser welding technologies enhance the sealing and adhesion between the parts of the case, reducing failures in enviroments with water (IP69K) and oil (IP67G).

Features and benefits:

1. Smallest body and longest sensing distance of 1,500 mm in its class. The E3AS Series, with a wide sensing range of 50 to 1,500 mm, eliminates the need to select different sensors based on application. Users can select either a model with a metal or plastic case to meet their installation environment requirements. Their small size enables installation in confined spaces.2. Detecting varying colors and materials enables fast evaluation and adjustment. With conventional photoelectric sensors, prior evaluation or positioning was required for each sensing object. The E3AS Series detects sensing objects varying in colors and materials by the set distance, reducing evaluation and adjustment time.

3. Industry-first antifouling coating prevents contamination on the sensing surface (Patent Pending). The antifouling coating on the sensing surface of the E3AS Series prevents water droplets, oil, and dust from sticking to the sensing surface, and keeps the lens from fogging as well. This reduces false detection and cleaning frequency.

4. Laser welding technologies for different materials/metals ensure sealing to avoid sensor failures (Patented). The E3AS Sensor case is made of stainless steel (SUS316L). Our patented laser welding technologies enhance the sealing and adhesion between the parts of the case, reducing failures in enviroments with water (IP69K) and oil (IP67G).

You might also be interested in this:

Phoenix Contact Axioline

Read further

The Axioline P modular proxy from Phoenix Contact connects PROFIBUS PA segments directly to a PROFINET network. The modular station communicates with a PROFINET controller, e.g., a distributed control system, via a bus coupler. As an option, up to eight PROFIBUS PA segments can be connected to the individual proxy outlets in a compact way. To ensure the individual segments are immune to interference, appropriate shield connection technology is available. FDT/DTM technology simplifies the startup and device management of both the proxy station, which is fully integrated into higher-level control systems, and the connected PROFIBUS PA devices. The AXL P BK PN AF bus coupler supports the specification for implementing S2 system redundancy using only one bus coupler. Two bus couplers are required in order to satisfy PROFINET system redundancy R1 and R2. The hot-swap capability integrated in the bus coupler ensures high system availability.

Phoenix Contact ClipX

Read further

Control cabinet manufacturing is characterized by a high proportion of process costs. This is therefore an ideal starting point for improving profitability in the production of machines and systems.

Phoenix Contact Valvetrab

Read further

Switching operations are far and away the most frequent cause of surge voltages. Type 2 surge protective devices provide effective protection against these dynamic disturbance variables. Whether in an industrial environment or in a residential building, type 2 protections ensures basic protection for your installations and devices.

Siemens Sitop

Read further

Experience the start of a new chapter in the world of standard power supplies with the SITOP PSU6200 all-around power supply. Whether you’re a builder or operator of control panels, machines, or plants, all users benefit from the ingenious functions and features of the new SITOP PSU6200 product line – throughout the entire lifecycle, from planning and engineering to installation and operation.